Water Gun Construction

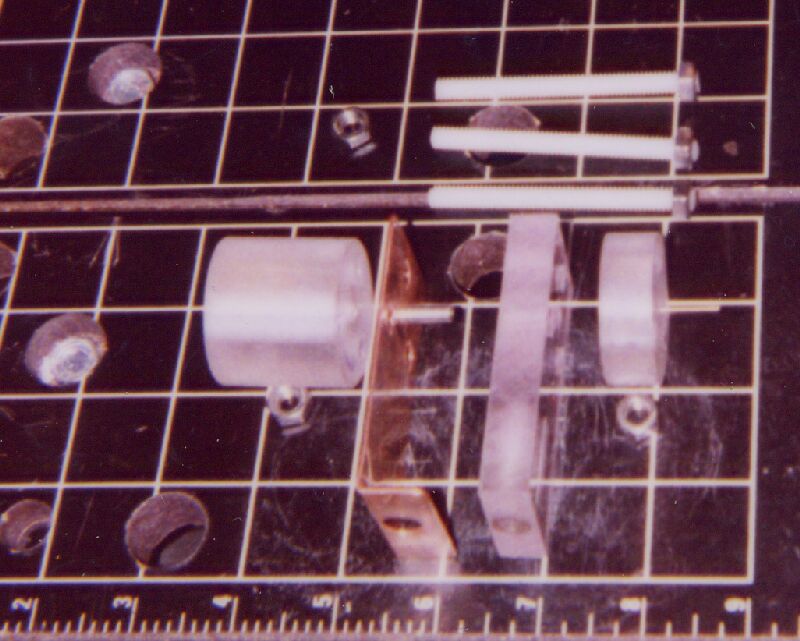

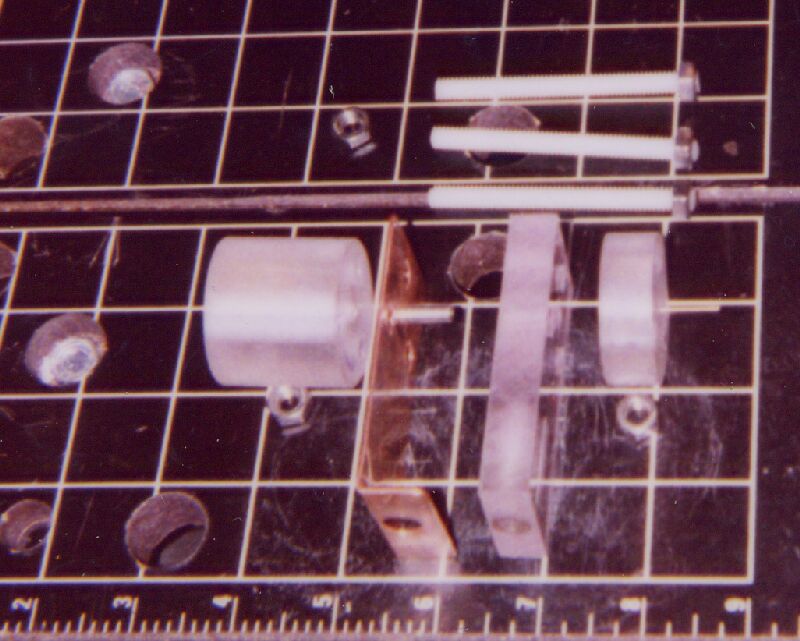

This is a two to one scale drawing of my attempt to reproduce

the launcher described in the patent. The muzzle end of the barrel

is formed from a 1.5" length of 3/32" ID X 3/16" OD high alumina ceramic

tubing (basically sapphire, actually closer to 13/64" OD). The breach

end is made from a 9/16" length of 3/32" ID X 3/16" OD 304 stainless steel

tubing. The breech is closed with a 0.5" length of 1.5" OD polycarbonate

rod carrying a 1" length of 0.040" OD tungsten welding electrode.

The ceramic tubing is epoxied into a 1.25" length of 1.5" OD polycarbonate.

The stainless steel tubing is press fit into a 3.625" X 1.5" X 0.0625"

copper sheet and slip fit into a 3" X 1.5" X 0.5" polycarbonate block.

The pieces are all held together with three threaded nylon rods.

The bottom of the rectangular block is drilled and tapped to accept the

3/8-16 terminal of my big pulse capacitors (see photos below).

This is a photograph of the pieces partially assembled.

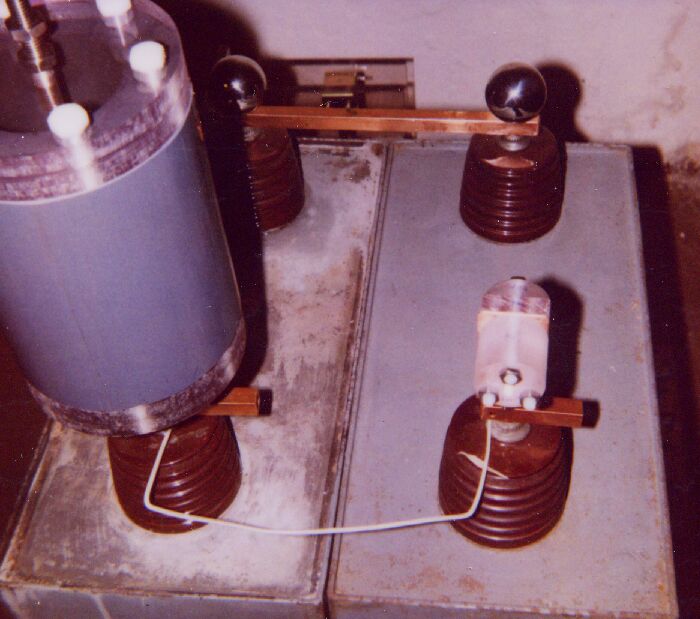

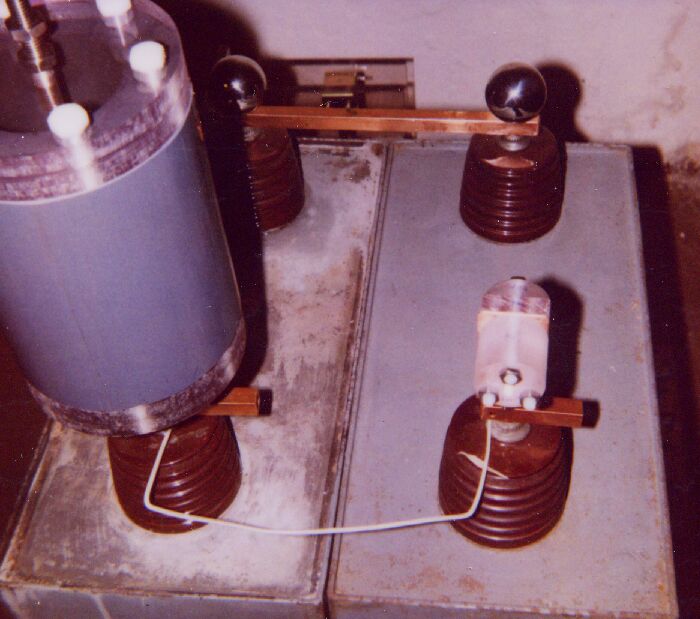

This is a picture of the assembled water gun mounted on my capacitor

bank. To the left of the picture is my triggered

spark gap. In operation, the output from the triggered spark

gap (off the top of this photo) is connected to the center electrode of

the gun via an air core inductor. The capacitors are charged and

fired just as in my can crusher.